ENGINES and PISTONS

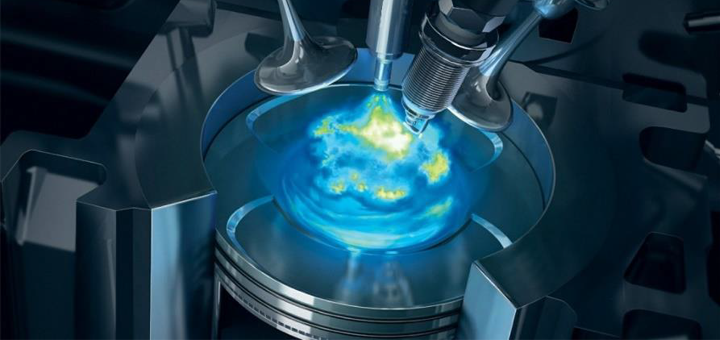

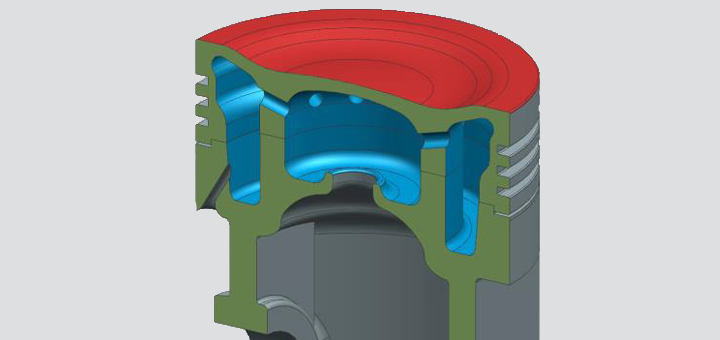

Piston cooling plays a critical role in modern engines. The intense heat generated during combustion threatens their structural integrity. Lightweight aluminum alloys, commonly used for lightweight pistons, exhibit strength reduction at elevated temperatures, necessitating a delicate balance between strength and weight. Additionally, sharp edges on the piston crown create hot spots. These localized temperature spikes can lead to carbonization and pre-ignition, compromising engine efficiency. Oil jets strategically target critical areas, such as the piston crown and ring lands, ensuring uniform temperature distribution. By directing cooling oil precisely, engineers mitigate hot spots, maintaining consistent performances.

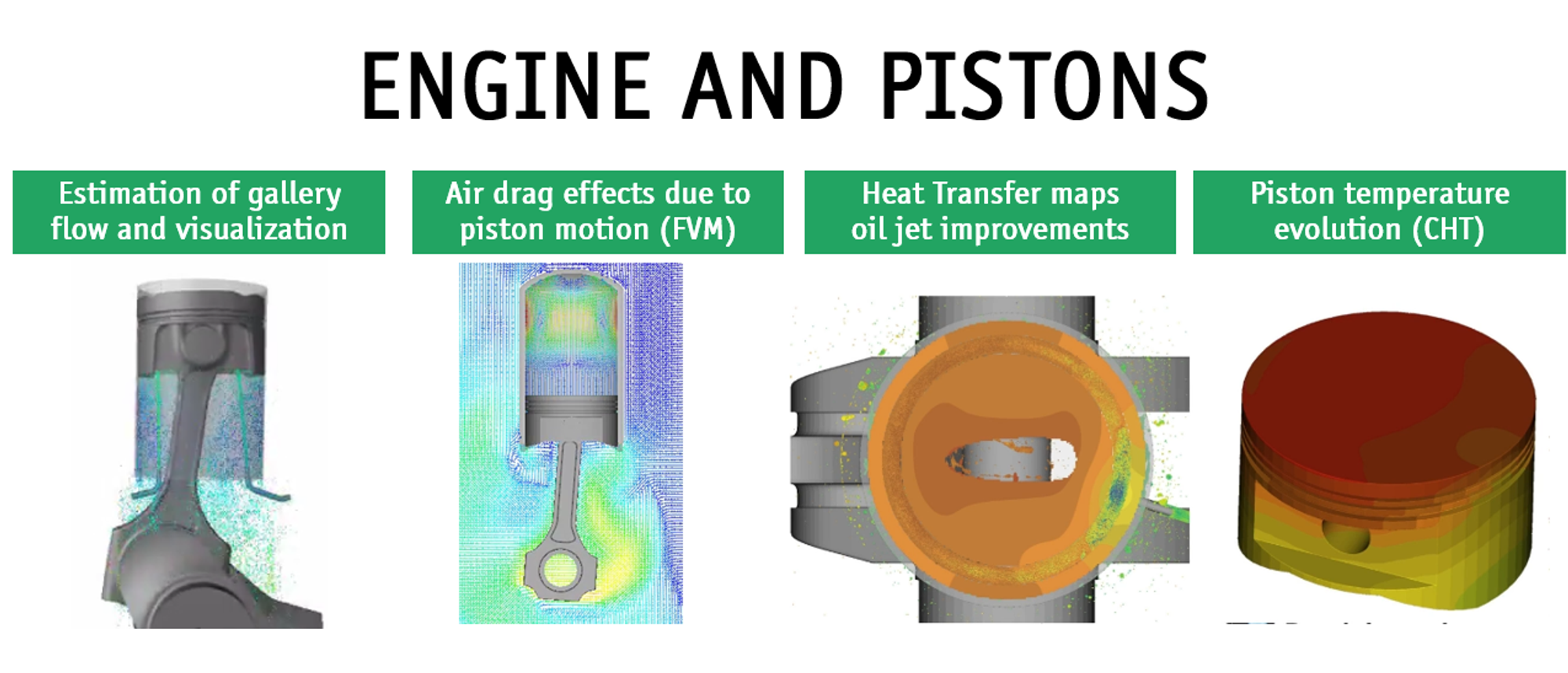

Particleworks creates digital prototypes of pistons and engines to investigate:

- Improvements of jet nozzle design

- Flowrate and jet direction impact on cooling capabilities

- Air drag effects on oil distribution due to piston movements

- Sloshing and accelerations influence cooling performances

- Piston design modifications for higher heat transfer coefficients